Vibrations are never invited in the world of machines. Be it cars, motors, machine tools, buildings and constructions or oil and gas platforms, vibrations create huge troubles for these industries.

And this is where the vibration absorber sets its foot in. Utilizing the rubber components design & manufactured by Sujan Industries, one of the pioneers among the top rubber companies in India, the vibration absorbers help to reduce the unwanted vibrations and ensure smooth running of the entire process.

Now let’s start the basics before we dive deep into the reasons for rubber being used in vibration absorption.

Vibration, in dynamic machines, occurs when there’s an imbalance of moving mass. It causes an undesirable vibration and stress that minimizes the durability of the machine.

Now, to get rid of the vibration, a tuned spring and secondary mass as a system are attached to the revolving apparatus. This technique is called vibration absorption and the mass-spring system is called vibration absorber.

Rubbers are compounded with such various additives that make it so versatile and useful for almost limitless numbers of industrial applications. Specifically, natural rubbers are valuable as spring materials for their longevity, flexibility, lower price and durability in high temperatures.

Besides, Rubber has enough high shear modulus compared to other materials. That means, when a rubber material is a stressed parallel to its cross-sectional area, it can be stressed more before it becomes completely deformed. Whenever rubber materials receive any vibrational stresses, rubber vibration absorbers absorb them before damage or transferring the vibrations. All these aspects make rubber a great component for vibration absorption, indeed. Hence, Rubber is the best material used as a vibration absorber.

Among various types of vibration absorbers, one that is used daily and widely is passive vibration absorber. This consists of a spring and damper. Whereas the spring softens the vibrations and pushes, the damper ends the oscillation. Mainly the spring acts as the absorber here and the damper helps the spring to do the task.

There are a handful of instances of the passive vibration absorbers that are used daily. One such instance found is the suspension bracket of an automobile. One can easily understand the operations of passive vibration absorbers and isolators by the way it works in automobile suspensions. The rubber parts found in every suspension bracket soften the push and impact of the road on which the automobile travels. Another element of the suspension found in an automobile is the shock-absorber.

Most of the time when we think of spring, an image of a spiral metal comes to our mind. But the spring used in Passive Vibration Absorbers has to be of rubber for different reasons.

With steel springs, there’s a linear relationship between the force and the bounce. But rubber springs can be designed to give varied stiffness in non-linear directions. Rubber materials are much more stretchable than steels before they get completely damaged.

Rubber products are easier and more convenient to handle and install than steel springs. Also rubbers have more capacity to store energy and when deflected it has the potential to convert some energy to heat. This is the reason why heat doesn’t spread in rubber much unlike steel.

Natural rubber without fillers can provide damping in a system subjected to vibrational forces. Thus unlike steel, the inherent damping ability in rubber makes it more potential as a vibration absorber.

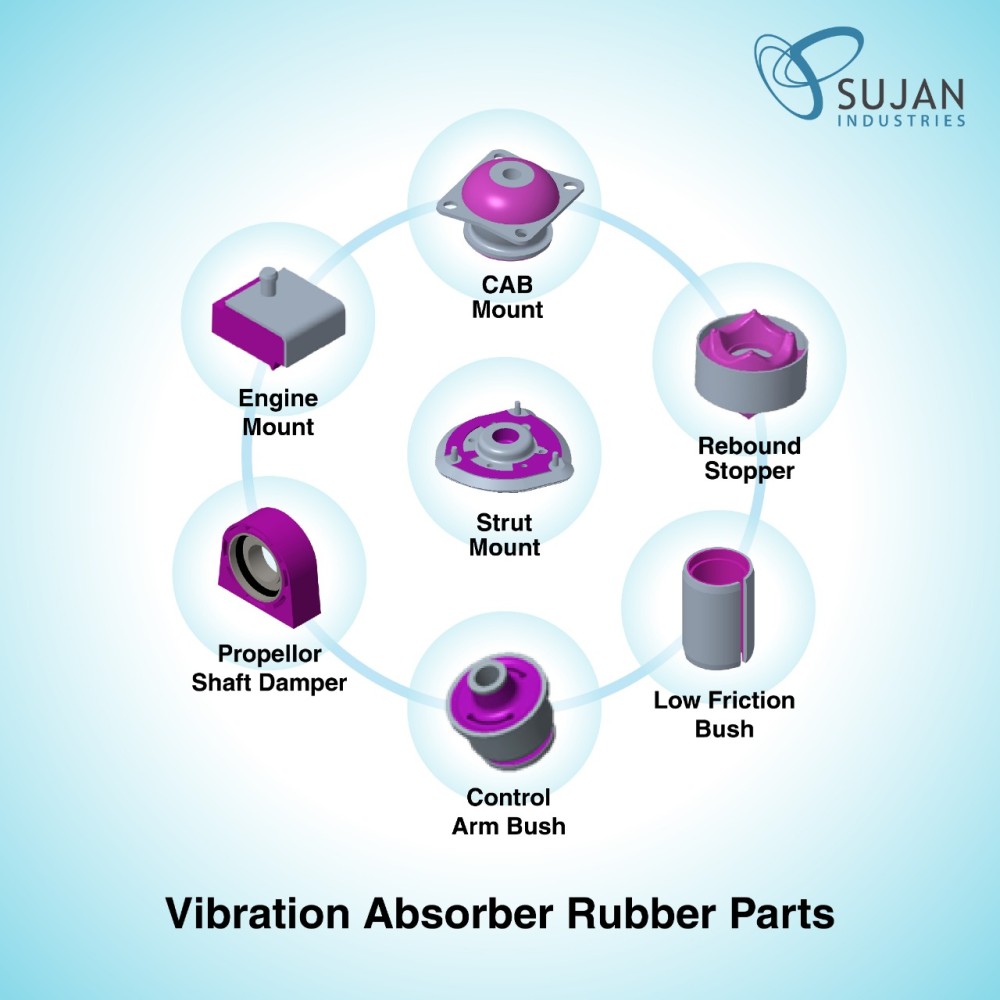

Sujan Industries is one of the largest rubber products manufacturers in India. It is an exceptional wing of the Sujan Group with multiple plants producing Rubber Parts, Antivibration components and Casting Components etc. World-class rubber goods for industrial applications and other such purposes produced in Sujan Industries includes, but not limited to, the following:

Apart from providing a wide variety of critical application anti-vibration rubber products that ensure excellent quality, high durability, low service intervals & more stability during working conditions, they also supply aftermarket products for Car, truck & trailer parts replacement.

Since inception Sujan Industries has always focused on Innovation & Creativity. Being a strong believer of the saying “innovation stimulates the progress of any organization,” they innovate in every way, be it new and improved products, techniques, practices of development & production and so on. The company heavily invests in research and development and keeps themselves up to date with the new introductions, requirements, trends and demands of the market.

Sujan Industries also provide design solutions and products to the core public sectors of India like:

Quality is the pride of workmanship. And Team Sujan Industries, with their approach to state-of-the-art equipment and a dedicated R&D department, extends the concept of excellence to the maximum. Committed to produce and supply only high quality products, they believe in the saying “Quality is never an accident; it begins with the intent, which is fixed by management.” Apart from the latest machinery, the company’s quality control system ensures excellence at every stage of production to manufacture premium products that are truly unparalleled.

To sum up, the natural properties of rubber like flexibility, firmness, stress resistance, endurance etc. makes the rubber an ideal material for absorbing vibrational forces in any machine.

Have more queries on rubber products? Get in Touch with us to explore new business possibilities.